Core technologies

|

Efficient protection:

Adopt IGBT high-speed protection technology, which can effectively protect IGBT from accidental occurrence and not burn out. |

Fiber optic transmission:

Because the internal power components of the induction heating power supply need to generate high-frequency and large-current, there is a large high-frequency strong magnetic field inside the cabinet, which greatly interferes with the transmission signals between various parts of the circuit and affects the normal operation of the device. Therefore, we use optical fiber to transmit important driving signals, which enhances the stability of the device.

|

|

|

Safe debugging mode:

When the process is debugged, the safety debug mode is turned on. The power supply can test the load matching situation, quickly find the resonance point and load match point, and record parameters such as the load resonance frequency, voltage, and current ratio to avoid damaging the workpiece during the process debugging stage and shorten Commissioning time to improve production efficiency; avoid causing damage to people and equipment. |

Intelligent power control:

Traditional analog power supplies are controlled by analog devices. The parameters are determined by analog devices such as potentiometers. These devices are significantly affected by the environment. For example, changes in temperature will cause parameter changes, resulting in power output without any adjustment changes at different times There is a difference.

|

|

|

Quick startup:

Under any load (no-load / full-load) and at any temperature (cold / hot), the device starts from full power output to less than 0.1 second, which greatly improves production efficiency, and also reduces the power and auxiliary equipment performance. Consumption, the startup success rate is nearly 100%, to avoid leakage heating. |

Variable frequency adaptive:

Adopts PLL-based adaptive frequency conversion technology to achieve instantaneous and accurate tracking of load changes at the inverter frequency, timely adjustment of inverter frequency and phase, ensuring that the IGBT always works in the ZCS state, and realizing the 'soft switching' of the IGBT to avoid Work under high voltage spikes, and effectively reduce IGBT and system losses, reduce IGBT heating, and achieve the purpose of efficient protection. |

|

|

Feedback line adaptive:

When replacing the load output line or moving the load, it is not necessary to consider the corresponding relationship between the load output line and the feedback line. The power supply will automatically determine the polarity of the feed line and make corresponding treatments. Necessary trouble. |

Fault self-diagnosis:

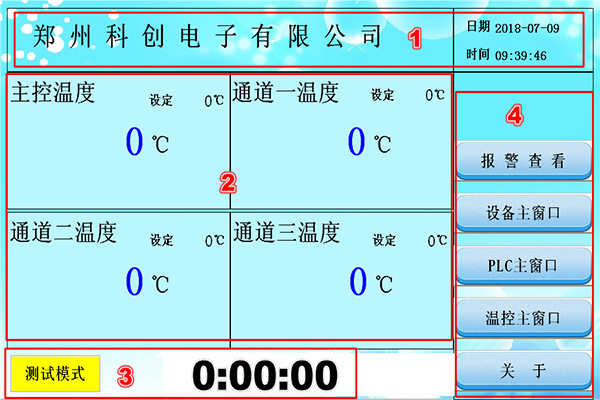

When the operator makes a mistake or an alarm occurs in a special working condition, the touch screen will display the fault content. Click the help of the corresponding fault to query the corresponding fault solution. Over 90% of common faults can be quickly handled by the operator, greatly improving production efficiency and reducing dependence on the technical level of the operator.

|

|

|

Powerful communication function and comfortable man-machine interface:

RS485 / 232 interface is reserved for data exchange with external controllers (industrial computers, industrial control touch screens, laptops, etc.) or the central control room. |

Process introduction

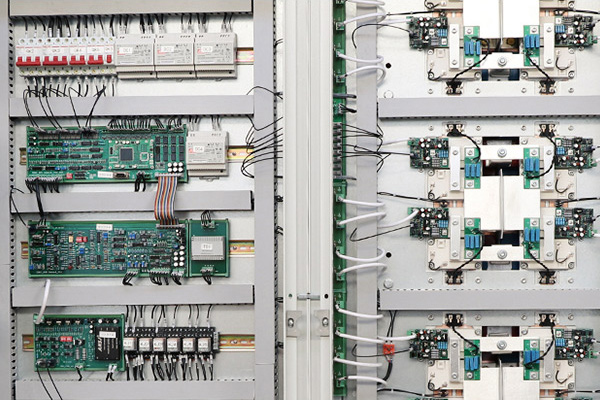

product structure:

The cabinet adopts Rittal structure and vertical plate installation method. PCB module design can prevent dust and static electricity. Water and electricity isolation for easy maintenance.

Product Protection:

The sealing tape is used to match the edge of the grooved box. The seal is good and reaches IP54 protection level. Dust, water vapor, and oil fume cannot enter the interior of the cabinet. Make each electronic device perform well at all times.

Device selection:

The key components on the equipment are all world-renowned brands, and the equipment runs more stable.

cooling system:

Power devices use efficient water-cooled radiators, which are safe and reliable. The cabinet uses industrial air conditioning, constant temperature control, and external environment isolation. Water circulation system adopts pure stainless steel metal structure.

Machine process:

Each connector has a number mark for easy maintenance and repair. The circuit board is fixed by a module rack, and the water channels are different colors. The joints of the copper bars are tinned, and the non-joins are treated with insulating paint.

(Comparison of development of induction heating technology)

Product innovation technology

1. Control core: Adopt Texas Instruments' high-speed digital signal processor (DSP) and use a dedicated Intel logic chip as the auxiliary processor.

2. IGBT or MOSFET is used as the main inverter device, combined with the efficient and fast resonance control method, the inverter efficiency is greater than 95%, and the host power factor is greater than 0.9.

3. Air-cooled, water-cooled and other structures are suitable for applications in various industries.

4. The equipment adopts all-digital high-efficiency fast resonance control mode, so that it can adapt to various parameters of the inductor and work in an efficient state. All series of power supplies have built-in digital PID temperature control modules, including user-programmable temperature control curve technology, and built-in multi-channel temperature measurement.

5. Built-in programmable engineering application IO interface: analog output, analog input, IO output and IO input interface, RS232 or RS485 communication interface.

6, the communication interface can be connected to a dedicated data logger.

7. The power adjustment adopts the stepless adjustment method, which can be adjusted from 0% to 100%, the division rate is registered with 0.1% or 0.01%, and the output stability is 0.3% or 0.025%.

8. The control interface adopts Chinese and English display, the display uses 7.0 inches, 10 inches, 15 inches, etc., and different levels of screens are used according to different applications.

9. The design life of the air cooling equipment is more than 12 years, and the design life of the water cooling equipment (except water) is more than 8 years.